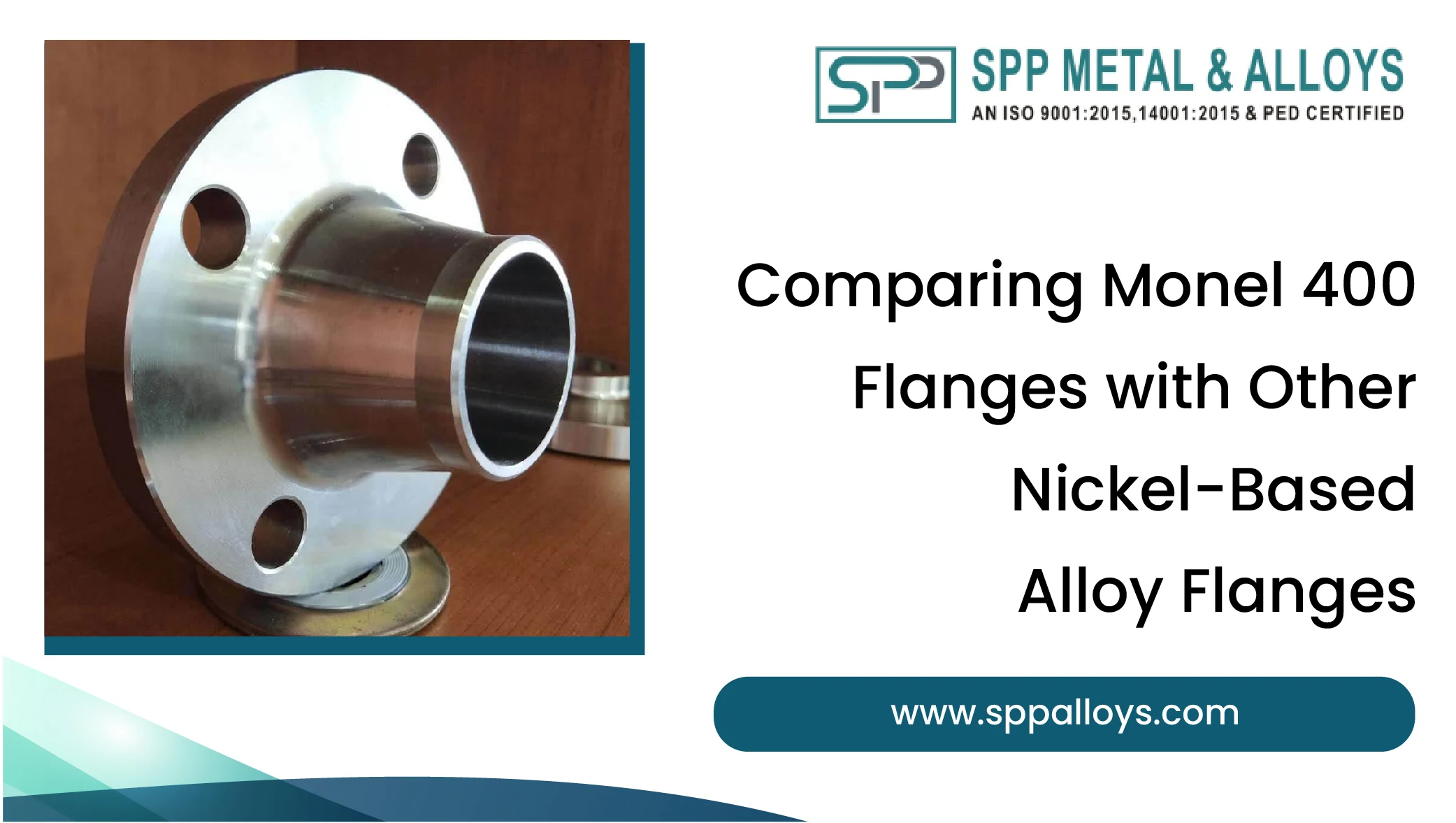

Comparing Monel 400 Flanges with Other Nickel-Based Alloy Flanges

Flanges are essential components in various industries, including oil and gas, chemical processing, marine, and power generation. They serve as connectors between pipes, valves, and equipment, ensuring a secure and leak-free connection. When it comes to selecting the right flanges for your application, it’s crucial to consider the material composition, specifications, welding procedures, and price. In this blog, we will compare Monel 400 weld neck flanges with other nickel-based alloy flanges to help you make an informed decision.

Monel 400 Chemical Composition

Monel 400 is a nickel-copper alloy known for its excellent corrosion resistance in a wide range of environments, including seawater and chemical environments. The chemical composition of Monel 400 typically consists of approximately 66% nickel and 31.5% copper, with small amounts of iron, manganese, carbon, and silicon. This unique composition gives Monel 400 its remarkable resistance to corrosion, erosion, and stress cracking.

Monel 400 Flanges Specifications

They are available in various specifications to meet different application requirements. The most common specifications include ANSI B16.5 and ANSI B16.47, which define the dimensions, pressure ratings, and facing types of flanges. It can be manufactured in different types such as weld neck, slip-on, blind, threaded, and socket weld, providing flexibility in design and installation.

Monel 400 Flanges Price

The price of Monel 400 can vary depending on factors such as size, type, quantity, and supplier. While Monel 400 is generally more expensive than carbon steel or stainless steel, it offers superior corrosion resistance and durability, making it a cost-effective choice in corrosive environments. It is essential to consider the long-term benefits and performance of Monel 400 flanges when evaluating their price.

Monel 400 Flanges Welding Procedure

Welding Monel 400 requires specific procedures to ensure proper bonding and prevent the formation of defects such as porosity or cracks. The welding procedure for Monel 400 involves preheating the material, using a matching Monel filler metal, and employing appropriate welding techniques. The use of specialized welding procedures and experienced welders is crucial to achieving high-quality welds and maintaining the integrity of the flanges.

Comparing Monel 400 with Other Nickel-Based Alloy Flanges

When comparing Monel 400 weld neck flanges with other nickel-based alloy flanges, several factors come into play, such as corrosion resistance, mechanical properties, availability, and cost. It stands out due to its exceptional corrosion resistance, making it suitable for demanding applications where exposure to corrosive environments is a concern. Its resistance to stress corrosion cracking, pitting, and crevice corrosion sets it apart from other nickel-based alloys.

In terms of mechanical properties, Monel 400 exhibits excellent strength and toughness even at elevated temperatures. It retains its mechanical integrity in extreme conditions, making it a reliable choice for critical applications. Furthermore, Monel 400 is readily available in various forms, including flanges, pipes, fittings, and fasteners, ensuring a consistent supply for industrial requirements.

In comparison to other nickel-based alloy flanges, Monel 400 may have a higher initial cost. However, considering its extended service life, reduced maintenance, and superior performance in corrosive environments, the overall cost-effectiveness of Monel 400 becomes evident. It provides long-term savings by minimizing the need for frequent replacements or repairs due to corrosion-related failures.

Conclusion

In conclusion, Monel 400 flanges offer unique advantages when compared to other nickel-based alloy flanges. Their exceptional corrosion resistance, mechanical properties, and availability make them an excellent choice for critical applications in various industries. While the initial cost may be higher, the long-term benefits and performance of it, justify the investment.

If you’re looking for reliable suppliers of Monel 400 flanges and other industrial raw materials, contact SPP Metals and Alloys. We are a leading manufacturer of flanges, fittings, and fasteners, and also stockist and suppliers of plates, sheets, pipes, tubes, and round bars. With our commitment to quality and customer satisfaction, SPP Metals and Alloys can provide you with the best quality materials for your specific requirements. Visit our website or contact them for more information.

Remember, choosing the right flanges is crucial for the integrity and efficiency of your systems. Consider the chemical composition, specifications, welding procedures, and long-term costs when comparing Monel 400 weld neck flanges with other nickel-based alloy flanges. By making an informed decision, you can ensure reliable and durable connections that withstand even the harshest operating conditions.